Air Ride vs. Hydraulics, it’s an age-old rivalry impacted by a lot of contemplation. By and large, these assemblies initially asked us to set ourselves at the height and provide the tilt equilibrium that we needed.

In any case, both of them have been the primary source of amazement in suspension for decades. However, compared to each other, these suspension systems contain lots of differences.

To old-school guys and souls steeped in tradition, hydraulics (based on water pressure) will be the way to go. On the other hand, we hold open the possibility that new-school people will go to the air ride option. Nevertheless, here’s a rundown of every system; see which one will work best in your vessel, so to speak.

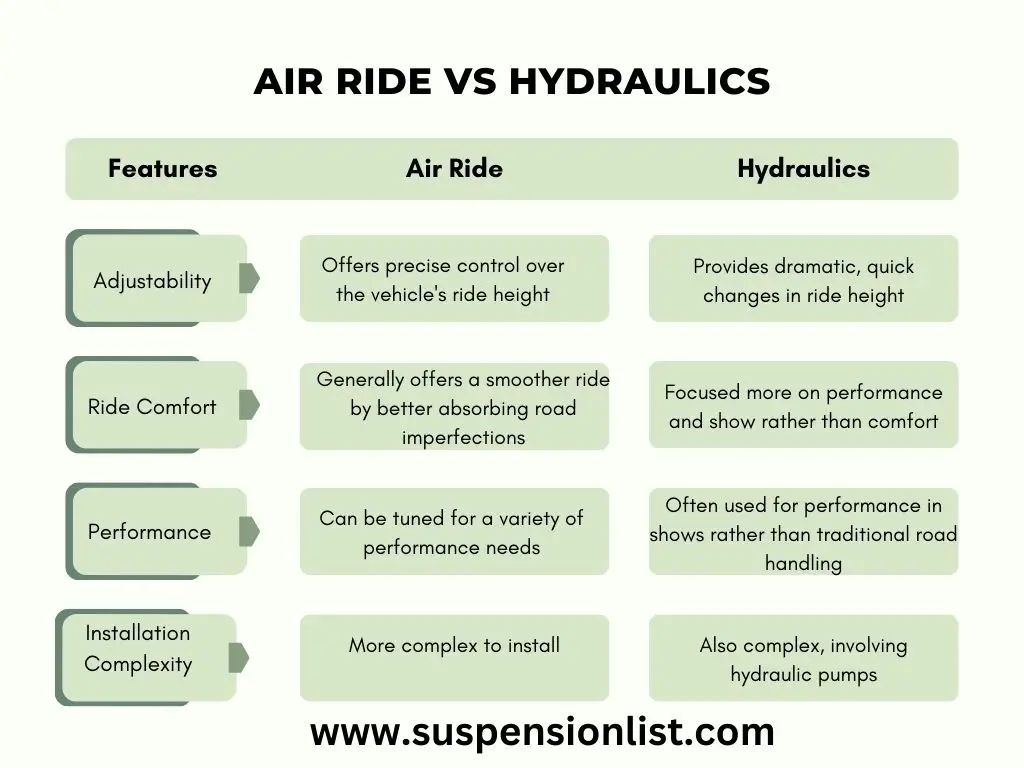

Air Ride Vs Hydraulics In a Table

What is An Air Ride Suspension?

An air-ride suspension is a kind of suspension that is classified as a pneumatic load-retaining device. A pressurized compressor supplies compressed air compressor fluid to airbags.

Typically, air-ride suspension systems are the standard for highway-bound trucks. Meanwhile, commercial vehicles, such as buses and ambulances, typically use compressed-air suspension systems.

What is Hydraulic Suspension?

A hydraulic suspension conversion kit can upgrade an older suspension to a more modern one. With hydraulic dampers, the kit uses a hydraulic suspension system that can pressure each one independently. During its operation, you can vary the lift to compensate for vehicle weight and operate the dampers as much as you want.

Much like any hydraulic system, there is a fluid known as the hydraulic fluid that creates pressure on the sealed system. This fluid produces power that is then transmitted to the various components in the system. In the case of a hydraulic suspension system, this power is what causes the chassis to rise off of the axle.

Air Ride vs. Hydraulics – A Real Comparison

As both Air and Hydraulic suspension systems are designed to provide the necessary height and stance adjustment according to our needs, it’s quite usual that there will be similarities. However, there are some noticeable differences as well. So, make sure that you’re well informed from the comparison below in case you’re shopping for a suspension system.

Working Mechanism

An air suspension evolves the stock coil springs into a system with airbags underneath. Of course, late-model coil spring suspensions can easily be replaced, as the spring-mounted bags are simple to slip in. Advancements in technology and machine parts make it simple to bolt on these systems without the need for cutting.

In opposition to the spring’s loading, the air chamber is compressed under load, causing a decrease in volume and an increase in pressure. Using the airbag, more air is pumped in, which relates it to an external high-pressure air chamber and causes an increase in stiffness.

The airbag consists of a pressurized air reservoir that uses air for inflation and lifting of vehicles that are complete with their compressor units. When the air pressure is being let free, the airbag deflates and thus lifts the vehicle. Experts have touted airbags for their smooth ride excellent handling and ability to control vehicle lift level.

Hydraulics systems use gas and oil rather than springs to gain traction in level and rough terrain under all-terrain vehicles. Hydraulic breakdown systems use hydraulic pressure to transmit motion between smaller parts of a system through actuators, such as the wheel in an automobile suspension system.

Fluids in the system may be pressurized using piston pumps, and pressure is transmitted from each chamber of the system to the following one via a valve called a damper valve.

Each chamber in the system possesses a piston with a compressed gas scenario against which the pumped pressure collides and rebounds. The force resulting from the rebound moves the oil back into the chamber from where it came, enabling the wheel to gather traction on the road.

Response

Air suspension systems are somewhat slower to respond to commands if you alter them while moving a car or truck. If you’re going to perform an exhibition, airbags may not be the optimal choice. As you may guess, airbags enjoy a high vertical”ascending” ratio.

Hydraulic fluid suspensions take up to 50 percent longer than airbag suspensions due to the hydraulic fluid being less engaging. If you desire a motor vehicle with an impressive performance that will leave people astounded, a hydraulic suspension might be the option for you.

Maintenance

Airbag systems take considerably similar upkeep to hydraulic ones. There is an increased risk that some system leaks, however many can be serviced, and the gift is less messy as long as you discover the leaks. Air leaks can occasionally be harder to detect than brake fluid leaks.

However, Hydraulic suspension systems tend to have more fluid leaks and will require the replacement of any seals, pumps, batteries, and fluids.

Ride Quality

Air-suspension systems are renowned for their smooth ride. That’s the main benefit of their system, as well as the reality, in this particular situation, that the smoother ride of airbags far outweighs their hydraulic counterpart. For this reason, they often suit luxury vehicles with more sophisticated features; they simply provide an altogether smoother ride.

While, due to the lack of compression that occurs in air, hydraulic suspensions provide a rough driving ride. A diverse system of springs and other components can be installed to make Hydraulic suspensions more forgiving. However, this additional expense causes the driver to have to work harder on the parts.

Cost

Air suspensions are quite inexpensive compared to hydraulic systems because they can start from the ground up. You can upgrade specific elements as needed, thus avoiding greater expenses when the truck needs to be completely overhauled. Hydraulic suspensions are more expensive in the setup phase, but they still provide a decent bar to go overboard with.

Pros and Cons of Air Ride Suspension

Let’s see what are the pros and cons of air ride suspension systems.

Pros:

- Lower noise levels, vibration, and harshness cause improved driving comfort, which may help reduce driver fatigue and discomfort.

- Trailers equipped with an air suspension typically last longer than those without this technology since the shock absorbers don’t pay tribute to as much vibration to the system components.

- The suspension system is not as negatively affected on the heavy truck due to how diminished the capacity is for harsh vibrations and impact.

- The shorter the wheelbase, the less jarring it is when a truck is unloaded from a station. Air suspension reduces the risk of a vehicle bouncing over rough terrain when it is empty.

- Unlike regular suspensions, air suspensions travel under the surface so that the journey lasts longer on the road.

- You can customize the air suspension for each ride based on the driver s wishes. Air suspension can be altered based on driving conditions, offering a cushy ride when traveling over smooth roads and then a harder ride for highway driving.

Cons:

- The weight of air suspension may make it harder to achieve fuel efficiency.

- Air leaks in the springs, or the compressor continuously engaging to maintain the proper air pressure, ultimately lead to a compressor burnout.

Pros and Cons of Hydraulics Suspension

Yes, we should also highlight the advantages and drawbacks of hydraulic suspension systems. There you go:

Pros:

- Hydraulic suspension systems are firmer and less likely to become fuzzy than airbag suspension systems.

- The hydraulic suspension provides a better driving experience since it’s much less responsive than a conventional coil spring suspension.

- When you bump a specific part of the road, the response from your car’s suspension will take effect quickly. This is because the levers are firmly connected to the independent hydraulic dampers and can be jolted independently of one another.

- Another added advantage of a hydraulic suspension lift is that it can be customized. For instance, you can adjust the resistance levels of shock in your vehicle by yourself.

- They allow you to adjust the car to show your created vision without compromising daily usage.

Cons:

- Setting a hydraulic lift can maximize the comfort in your road driving experience, but buying this linkage system is somewhat costly if you’d rather have the standard version. If you just make a hydraulic suspension kit or use a motor vehicle that has this setup in it, expect to pay a lot more than a steel spring suspension vehicle or a kit.

- Another possible drawback is the vulnerability to hydraulic leaks that can cause setbacks for the entire suspension system. When it comes to a pin or cotter sticking, all it takes is one part to become damaged or worn, and hydraulic liquid will start leaking. This will have a serious influence on the complete suspension system.

Final Words

Considering that your desired level of performance differs, who is the winner of the Air Ride vs. Hydraulics battle is completely up to your capability and requirements. A hydraulic suspension kit is your ideal bet if you are looking for a full-scale upgrade.

To improve your carrying capacity and lessen the amount of bouncing that takes place during driving trips, install an air suspension. It’s a matter of personal flavor and what you want.

More differences: